Tutorials

A Guide to Laser Engraving Slate Coasters

Estimated reading time: 6 minutes

Key Takeaways

- Preparation is Paramount: The quality of your engraving is determined before the laser ever turns on. Thoroughly cleaning the slate and applying a contrast-enhancing coat of mineral oil or clear lacquer is the secret to achieving a sharp, high-contrast design.

- Balance Power and Speed: The core of laser engraving slate is managing energy delivery. A combination of high power and slow speed produces the brightest, whitest mark. Conversely, low power and high speed result in a subtler etch.

- Always Run a Test Grid: Never engrave your final product without first testing your settings on a scrap piece of slate from the same batch. A material test grid helps you pinpoint the exact power and speed combination for optimal results, saving time and materials.

- Finish for Durability: After engraving, clean off the dust and apply a final seal. Using food-safe mineral oil or a clear matte sealant not only enhances the visual contrast but also protects the coaster from moisture and scratches, ensuring a long-lasting, professional finish.

Table of Contents

- Selecting and Preparing Slate for Engraving

- Optimal Laser Engraving Slate Settings

- The Engraving Process and Finishing Touches

- Conclusions

- Frequently Asked Questions

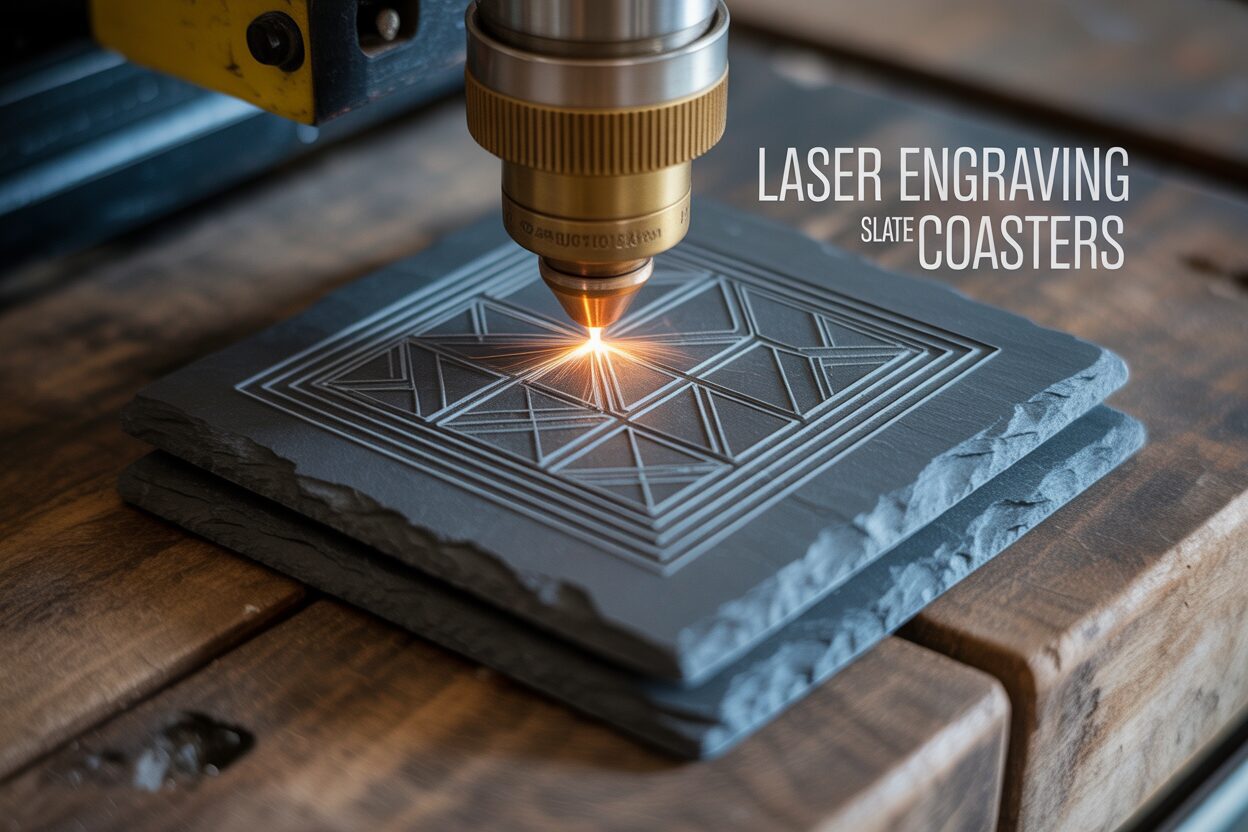

Discover the art of transforming simple slate coasters into personalized masterpieces. This guide offers everything you need to know about laser engraving slate coasters, covering material preparation, ideal settings, and finishing techniques. Whether you’re a hobbyist or a professional, you’ll learn how to laser engrave slate with precision, creating stunning and durable designs that are sure to impress.

Selecting and Preparing Slate for Engraving

The foundation of a stunning engraved slate coaster is not the laser, but the slate itself. The quality of your raw material directly dictates the quality of your final product, making this initial selection and preparation phase one of the most critical steps in the entire process. Rushing this stage can lead to inconsistent results, focusing issues, and a final product that lacks professional polish.

Interested in more Slate Coaster? Check out our Slate Coaster laser file designs: Click here!

Choosing High-Quality Slate

When sourcing your slate coasters, pay close attention to three key characteristics: surface flatness, thickness, and color consistency. Slate is a natural material, and variations are expected, but minimizing them will save you significant time and frustration. Look for coasters with a relatively smooth, flat surface. While a natural, slightly riven texture is part of slate’s charm, extreme peaks and valleys will cause focusing problems for your laser. The laser beam has a very specific focal point, and if the surface height varies by more than a millimeter or two, parts of your design will be crisp and sharp while others will be blurry and weak. Similarly, check for consistent thickness across the coaster and from one coaster to another in a batch. If you are using a jig to engrave multiple coasters at once, a significant difference in thickness will throw off the focus for the thinner or thicker pieces. Finally, inspect the color. Look for a deep, uniform dark gray or black. Lighter-colored slate or slate with significant mineral deposits or color variations will result in a lower-contrast engraving, as the laser-etched areas will not stand out as prominently.

Preparing Slate for Engraving

Once you have selected your slate, proper preparation is essential to achieve that coveted high-contrast, sharp engraving. Raw slate is often dusty and may have oils from handling that can interfere with the laser. The real magic, however, comes from pre-treating the surface to darken it, which makes the lighter engraved portion pop. Follow these steps for perfect preparation:

- Step 1: Clean the Surface. Begin by thoroughly cleaning each coaster. Use a soft cloth dampened with isopropyl alcohol to wipe down the surface. This effectively removes any slate dust, fingerprints, and oils without leaving a residue. Alternatively, you can wash them with mild soap and water, but you must ensure they are completely dry before proceeding to the next step. Any moisture left on the surface can cause inconsistent engraving and potentially damage the material.

- Step 2: Apply a Contrast-Enhancing Coat. This is the secret to achieving a dark, rich background that makes your design stand out. You have two primary options. The first is to apply a very thin coat of food-safe mineral oil. Use a lint-free cloth to wipe a small amount of oil evenly across the coaster’s surface, then use a clean, dry part of the cloth to buff off any excess. You want to enrich the color, not leave a greasy film. The second option, often preferred for a more durable and permanent finish, is to apply a thin layer of a clear matte or satin spray lacquer. Spray a light, even coat from about 8-10 inches away.

- Step 3: Cure and Dry. Whether you used oil or a clear coat, this step is non-negotiable. You must let the surface cure completely. For mineral oil, allow it to sit for at least a few hours. For a spray lacquer, follow the manufacturer’s instructions, but allow at least 24 hours for it to fully cure before taking it to the laser. Engraving on a tacky or wet surface will result in a gummy, messy engraving and produce unpleasant fumes. This pre-treatment works by darkening the slate. When the laser engraves the surface, it ablates the clear coat/oil and the very top layer of the slate, exposing the lighter gray stone underneath. This creates a brilliant contrast between the dark, prepared surface and the light, engraved design, elevating your project from good to exceptional.

Optimal Laser Engraving Slate Settings

With your slate coasters cleaned, pre-treated, and ready, it’s time to configure your laser. Dialing in the correct settings is a delicate balance of science and art, turning a prepared piece of stone into a finished product. The three core parameters you will manipulate are Power, Speed, and Resolution. Understanding their interplay is the key to mastering slate engraving.

The Core Settings: Power, Speed, and Resolution

Think of laser engraving as applying a controlled amount of energy to the slate’s surface. The laser isn’t burning the slate but rather fracturing and ablating the top layer, exposing the lighter gray stone beneath. The combination of Power and Speed dictates how much energy is delivered to any given spot.

- Power: This setting, usually expressed as a percentage (0-100%), controls the output intensity of the laser beam. Higher power delivers more energy, resulting in a brighter, whiter, and more pronounced mark.

- Speed: This determines how fast the laser head moves across the material, typically measured in millimeters per minute (mm/min) or millimeters per second (mm/s). A slower speed means the laser beam dwells on each spot for longer, delivering more energy.

- Resolution: Measured in Dots Per Inch (DPI) or Lines Per Inch (LPI), this setting defines the spacing between engraved lines. A higher DPI (e.g., 300) creates more overlap between lines, resulting in a solid, fully filled appearance. A lower DPI (e.g., 150) will have visible lines and is faster but may look less refined. For most slate designs, a DPI between 250 and 300 is ideal.

The relationship is straightforward: to get a strong, bright white mark, you need a high amount of energy. This can be achieved with high power and slow speed. Conversely, for a subtler, lighter gray mark, you would use low power and high speed. Finding the perfect balance for your machine and material is the goal.

Starting Points for Diode Lasers

Diode lasers are exceptionally well-suited for engraving slate. They operate at a wavelength that interacts very effectively with the stone, producing excellent contrast. While every machine and batch of slate is slightly different, here are some reliable starting points for common diode laser output powers. Note that these assume you are engraving pre-treated slate as described in the previous chapter.

Sample Diode Laser Settings for Slate (Starting Points)

5W Diode Laser:

- Speed: 1000 mm/min

- Power: 85%

- DPI: 254

10W Diode Laser:

- Speed: 3000 mm/min

- Power: 60%

- DPI: 280

20W Diode Laser:

- Speed: 5000 mm/min

- Power: 45%

- DPI: 300

The Unskippable Step: The Test Grid

The settings above are merely starting points. Variations in slate density, the exact thickness of your pre-treatment coat, and the true power output of your laser make testing a mandatory step. Never engrave your final product without first running a test grid on a scrap piece from the same batch. Most laser software (like LightBurn) has a built-in feature to create a material test grid. This engraves a matrix of squares, each with a different combination of power and speed. By visually inspecting the grid, you can pinpoint the exact settings that produce the crisp, bright white mark you desire for your specific setup. This five-minute test will save you from wasting coasters and ensure perfect, repeatable results every single time.

The Engraving Process and Finishing Touches

You have selected your slate, perfected its surface, and dialed in your laser settings through careful testing. Now it is time to bring everything together and create your final product. This chapter details the workflow from positioning your coaster on the laser bed to applying the final protective finish.

From Digital File to Physical Engraving

With your design file loaded into your laser control software and the optimal settings from your test grid applied, the physical setup is the next crucial step.

- Step 1: Positioning the Coaster. Place your pre-treated and fully dried slate coaster onto the laser bed. For a single coaster, placing it in the center is fine. If you are producing a set, consistency is key. Creating a simple jig out of scrap wood or cardboard with a cutout the exact size of your coaster will allow you to place each one in the identical spot, ensuring your design is perfectly centered every time. This eliminates guesswork and guarantees a uniform batch.

- Step 2: Focusing the Laser. A sharp focus is non-negotiable for a crisp, detailed engraving. Because slate can have a slightly uneven surface, it is best to find an average focal height in the center of the area you plan to engrave. Use the focusing block or distance tool provided with your laser to set the correct height between the laser lens and the slate surface. An out-of-focus laser will produce a wide, blurry beam, resulting in a muddy and indistinct design. Take a moment to get this right; it makes a world of difference.

- Step 3: Framing and Running the Job. Before you press start, use your software’s “Frame” or “Trace” function. This will move the laser head around the outer boundary of your design without firing the laser, allowing you to visually confirm that the placement is correct. Adjust the coaster’s position as needed until the frame is perfectly centered. Once you are satisfied, secure your safety glasses, ensure your ventilation is running, and begin the engraving job. Never leave a running laser unattended.

Finishing Touches for a Professional Result

When the laser has finished its work, the engraving will be covered in a fine layer of light gray dust. The final steps of cleaning and sealing will remove this residue and enhance the contrast for a stunning, durable finish.

- Step 1: Initial Cleaning. Carefully remove the coaster from the laser bed. Use a soft-bristled brush (an old toothbrush works well) to gently brush away the majority of the engraving dust. Afterward, wipe the surface with a lint-free cloth dampened with isopropyl alcohol or water. You will immediately see the contrast sharpen as the dark, pre-treated slate is revealed beneath the light dust, making the bright white engraving pop.

- Step 2: Sealing and Protecting. This final touch not only enhances the appearance but also protects the coaster. You have two excellent options. For a natural, rich look, apply a small amount of food-safe mineral oil to the coaster with a clean cloth, then buff off any excess. This deepens the black of the slate and makes the engraved areas appear even brighter. For a more permanent and water-resistant finish, apply one or two very light coats of a food-safe clear sealant spray (a matte or satin finish is recommended to preserve the natural look). Allow it to cure completely according to the manufacturer’s instructions. This step locks in the contrast and protects your beautiful engraved slate coasters from moisture and scratches, ensuring they look great for years to come.

Conclusions

You now have the knowledge to create beautiful, high-quality engraved slate coasters. By carefully preparing your material and mastering your laser engraving slate settings, you can produce professional-grade products. Don’t be afraid to experiment with different designs and settings to find what works best for your machine and material. Start creating your own custom slate coasters today!

Frequently Asked Questions

Q: Why is my slate engraving blurry or inconsistent?

A: This is most often caused by an incorrect focal distance. Slate’s naturally uneven surface can be tricky, so focus on the average height of your engraving area. Blurriness can also occur if you engrave on a pre-treatment coat (like lacquer or oil) that has not fully cured.

Q: What is the best way to get a high-contrast, bright white engraving on slate?

A: The key is a two-part process. First, prepare the surface by cleaning it and applying a contrast-enhancing coat like mineral oil or a clear matte spray to darken the slate. Second, use a combination of high laser power and slow speed, which you’ve perfected by running a test grid on a scrap piece first.

Q: Can I use any type of slate for laser engraving?

A: For the best results, choose high-quality slate that is as flat as possible, consistent in thickness, and has a uniform dark color. Extreme variations in surface height will cause focusing problems, and color inconsistencies will lead to a lower-contrast final product.

Q: Do I have to seal the coasters after engraving?

A: While it’s not strictly mandatory, sealing is highly recommended. It protects the coaster from moisture and scratches, significantly enhances the contrast between the dark slate and the light engraving, and gives the final product a professional, durable finish that will last for years.

Block "subscribe-popup" not found